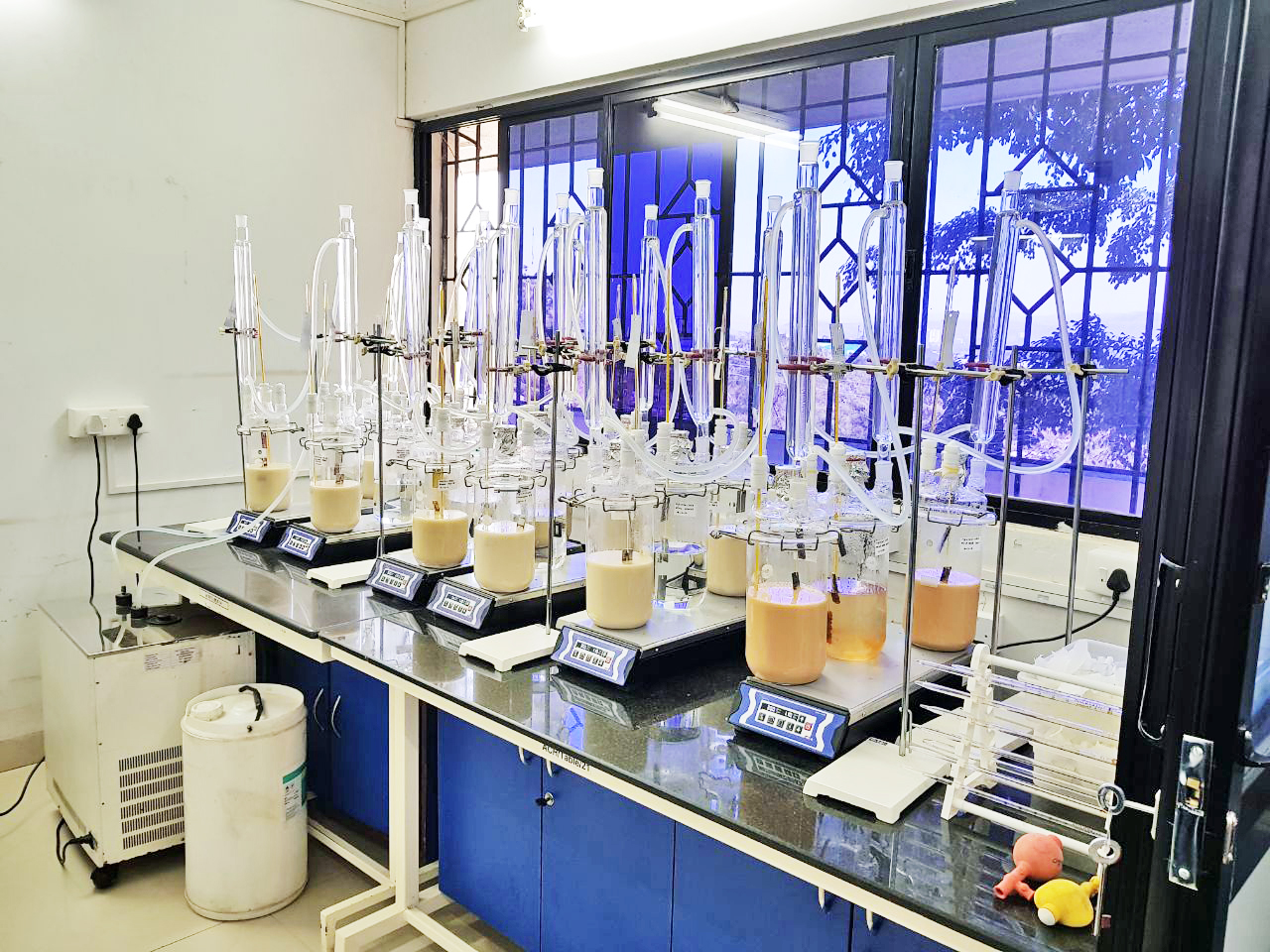

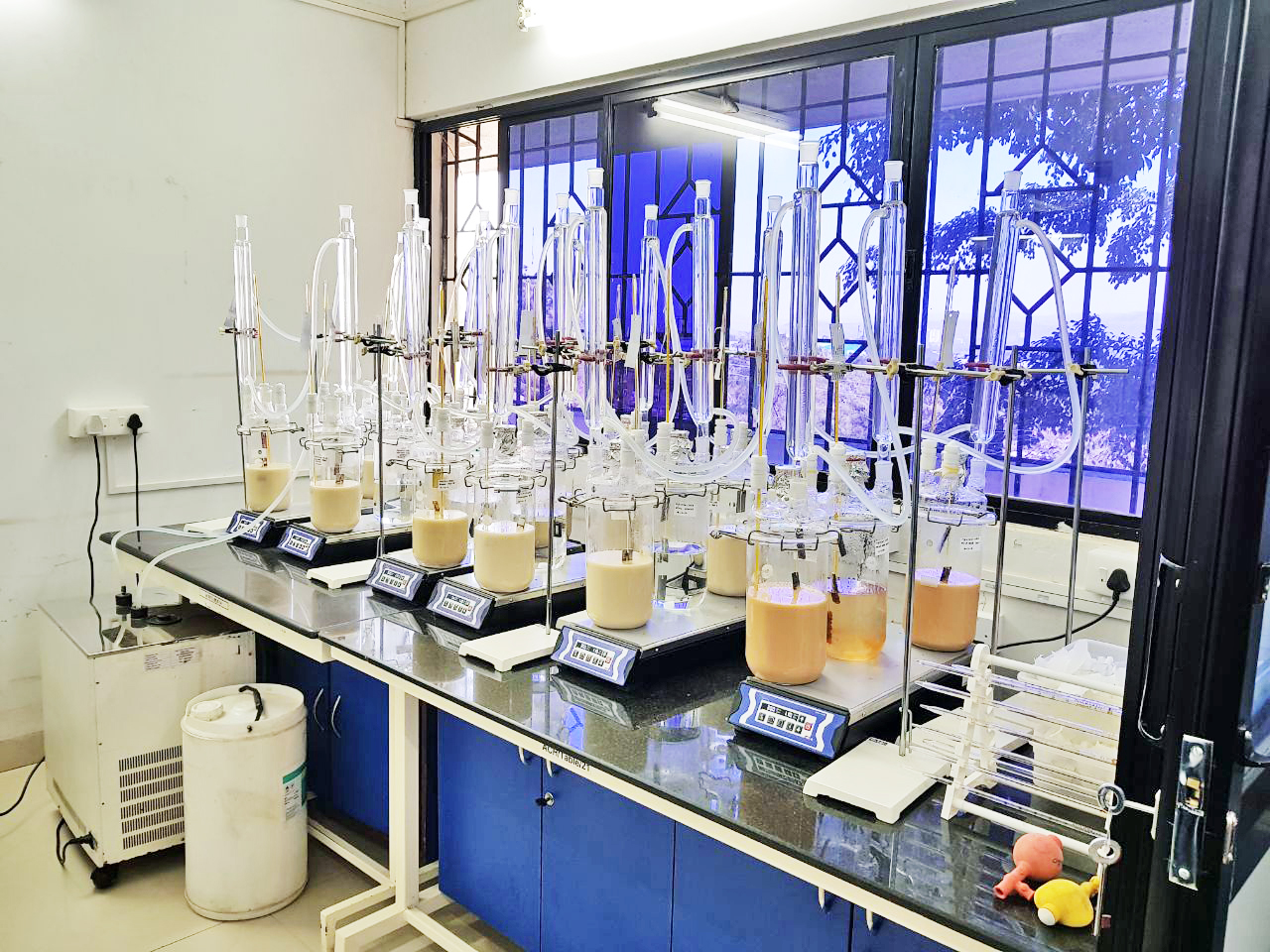

The objective is to test the immersion corrosion of metals and alloys in the presence of test article. The test article is placed in contact with various metals such as aluminium, copper, zinc, stainless steel, mild steel, and brass, to generate data on compatibility of test article with metal(s) and alloy(s), as required. Studies to assess corrosion are performed as per guideline ASTM G31, which describes the factors that influence laboratory immersion corrosion tests, particularly mass loss.

The study is performed in compliance with the study plan which incorporates recommendations made in the following: ASTM Designation: NACE TM0169/ G31-12a “Standard Guide for Laboratory Immersion

Corrosion Testing of Metals” Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

Aluminium, Copper, Zinc, Stainless steel, Mild steel, Brass.

Aragen holds substantial proficiency in conducting immersion corrosion tests, adhering to relevant protocols, and ensuring that all investigations adhere to the principles of Good Laboratory Practice (GLP).

Over the past half-decade, we have executed immersion corrosion assessments for over 50 different test subjects in the presence of different metals and alloys. The outcomes and findings from these corrosion

tests have been submitted to various regulatory authorities.

Aragen Life Sciences is a leading contract research, development and manufacturing organization offering end-to-end integrated and standalone solutions for pharmaceutical, biotechnology, crop protection and industrial chemical industries. For more information on our services and to speak with our subject experts, write to us at bd@aragen.com.